Tuning viscosity in glaze (thanks, I hate it)

For you who have been following along with my development of a deep iron saturated crystal glaze, you will know that somewhere around 2023 I succeed. From this I made three different recipes. The first one was what I think AMACOs’ recipe for ancient copper is at cone 6 ox (which is the range for all of these glazes). The second was my own, Ancient Greymon. A non lithium carbonate version of the glaze. It works very well if applied correctly. The third was Red lotus, A version of Ancient Greymon that I sold to a company. This version turns a deep red when used and if applied correctly it makes small red crystals. So, Three recipes in total.

Of course I have and continue to do extensive testing with all of these glazes. Everything from application to specific gravity to viscosity testing. I test out a range of these from high to low, from cone 4 -6 ox. So of course I need at test low specific gravity with 1-4 seconds of application to high specific gravity with 1-2 seconds of application. But I have a problem… The glaze started cracking when applied spooky sounds . Just to be clear, This is not crazing. Crazing on pottery is when cracks happen in the glaze matrix after firing due to the difference in the thermal expansion of the clay and glaze trying to fit each other after a glaze firing. This problem is occurring before the firing process and seems to be exacerbated by thickness. Here, let’s take a look.

Ancient copper(?) on a redstone clay body.

5 Layers brushed on

1.4 Specific gravity

Ancient copper(?)

Dipped for 3 seconds

1.4 Specific gravity

Ignore the little bubbles, I assume it’s just oxygen escaping the pours of the glaze when applied. It will not hurt the glaze and is of no concern

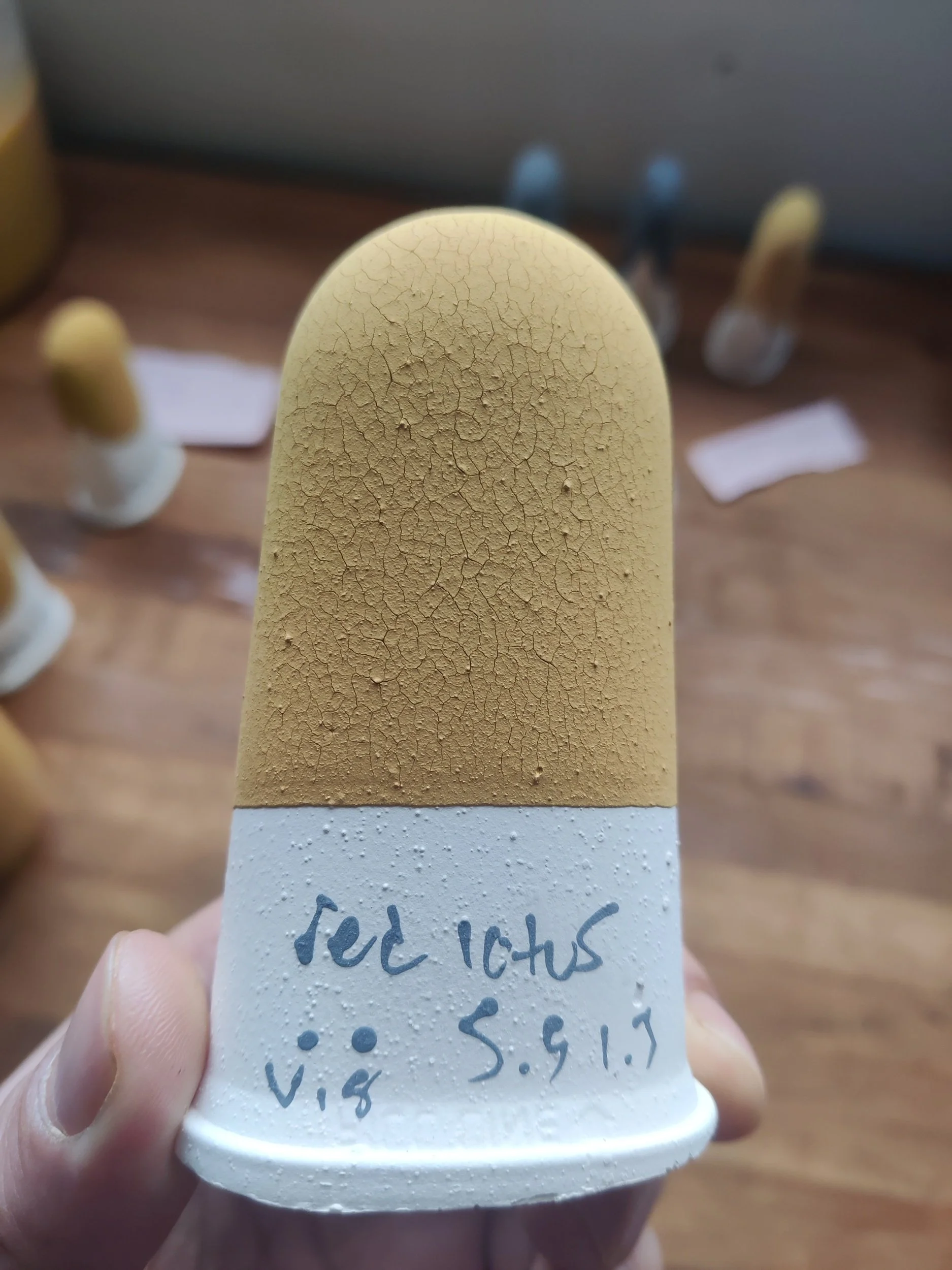

Red Lotus (clayscapes recipe)

4 second dip

1.3 Specific gravity

Viscosity 18 seconds with a zhan #2 cup

Do you see the cracking? even with lower specific gravity aka more water in the glaze? This is because I added sodium solution to this one. Effectivly increasing the velocity.

Red Lotus (clayscapes recipe)

5 second dip

1.3 Specific gravity

Viscosity 18 seconds with a zhan #2 cup

The cracks got even bigger with a 5 second dip!

Still have sodium solution added to the glaz)

Ancient Greymon

This is my personal version of the crystal glaze I developed.

4 second dip

1.25 specific gravity

No cracks so far.

At this point I start seeing a correlation between the cracks and the thickness of application. So I chose to do another test on the same clay body but lower the application to 3 seconds with 1.3 specific gravity.

Red Lotus (clayscapes version)

2 second dip

1.3 Specific gravity

Viscosity 18 seconds with a zhan #2 cup

Ok, so the cracks got smaller…. that’s good. but it doesn’t solve my problem. I need to test this thing out at 1.4 - 1.5 specific gravity. But we can see here that thickness and velocity does effect the cracking.

At this point I remember something. I have been tuning the viscosity of these glazes with Epsom salt solution and Darvan 7…. back and fourth. I thought this could be part of them problem. So I made a new batch of red lotus and ancient copper to test…. And guess what.

Red Lotus (clayscapes recipe)

The tile on the left is the new batch while the right is the cracked batch that had Epsom salt solution and Darvan 7. I even raised the specific gravity up by 0.1 (which is that I wanted to test in the first place)

All I wanted was a way to test Red lotus or Ancient greymon at 1.5 specific gravity…. of course were still going to fire all of these tests.

One thing I have learned though, If the viscosity of a glaze or application is too high the glaze cracks. There seems to be a correlation between these cracks and crawling. I do not think one causes the other, but its’ not helping it.

Of course I fired all of the above tests anyway. Had to see the results of this super cracked glaze.

Ancient copper(?) on a redstone clay body.

5 Layers brushed on

1.4 Specific gravity

Forced to cone 6 ox

Ancient Copper (?)

Dipped for 3 seconds

1.4 Specific gravity

Ignore the little bubbles, I assume it’s just oxygen escaping the pours of the glaze when applied. It will not hurt the glaze and is of no concern

Fired to cone 6 ox

Red Lotus (clayscapes recipe)

4 second dip

1.3 Specific gravity

Viscosity 18 seconds with a zhan #2 cup

Do you see the cracking? even with lower specific gravity aka more water in the glaze? This is because I added sodium solution to this one. Effectivly increasing the viscosity.

Fired to cone 6 ox

Ancient Greymon

This is my personal version of the crystal glaze I developed.

4 second dip

1.25 specific gravity

Fired to cone 6 ox

Red lotus Zenith

3 second dip

1.4 specific gravity

Fired to cone 6 ox

This one has no viscosity tuning whatso ever; his is a new batch.

Red lotus

2 second dip

1.3 specific gravity

Viscosity measured with a zhan #2 cup = 18 seconds

This is the most surprising one by far. Tuned in with epsom salt solution and darvan 7 (I was going back and forth). A little cracking on application. Weirdly enough this tile turned out great.

But do you see?!?! Do you see how many different results I am getting from some of the same glazes while just tuning in the S.G and the viscosity?! It matters a lot. So what did I learn? I think if you are going to tune viscosity with either darvan (811 or 7) or Epsom salt solution, you need to pick one. It’s not a scale in which you can go back and fourth without consequence. Of course at the moment I cannot prove this with 100% certainty, but I do think I have enough correlation to make a connection. It seems viscosity cannot be treated like and straight line back and fourth scale, made to tune and play with. I think from this point it would be wise to pick a direction and go with it. Either use a de-flocculent or a flocculent. Do not tune one glaze with both back and forth willy nilly.