Glaze calculator confusion

Because of my glaze work and content on both youtube and my website I often get messages or talk to people who either want to pick my brain about glaze chemistry or ask about something they are having trouble in. A great example is my blog in making cone 5/6 oxidation red glazes. Many people have trouble with them either turning black or brown. This is a difficult color to achieve without a graveyard of test tiles or a mass amount of experience. Not only do you need to know the molar amounts in the UMF but you also need to know how each material works; some of them absorb a lot of water, some of them need viscosity tuning, some of them need a specific application to work. This is the reason why i released the Glazy calculator molar amounts for iron saturated Kaki reds on one of my previous blogs. People can follow that without a recipe and get very very close to home. But here is the problem.

Every now and then I meet someone very experiences in the field that is trying to follow my molar amounts to make a red and it’s just not working. Of course I talk to them, watch their process, how they do what they do and why. At times I can find the error quickly; They used too much water, applied way too many coats, did not follow viscosity instructions, but sometimes it’s as simple as the glaze calculator you are using. Let me explain. Let’s take one of my public recipes, Laogia Green.

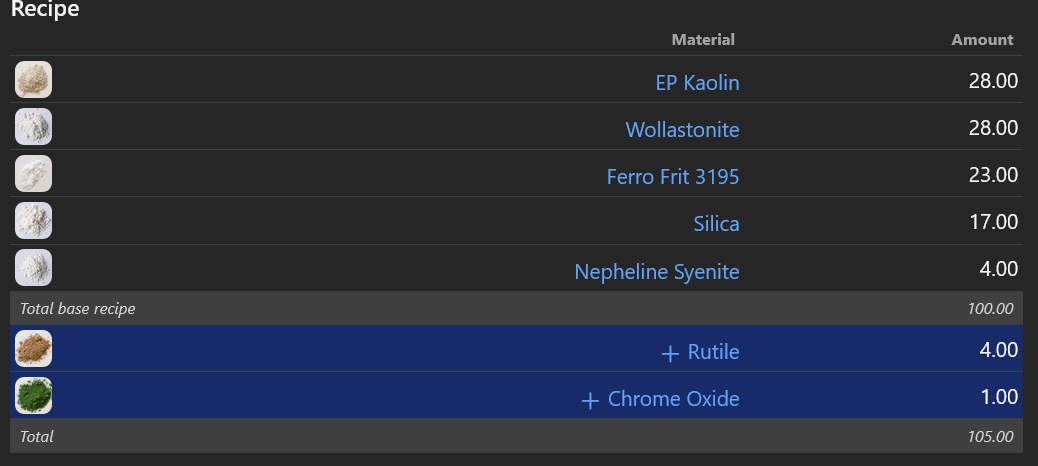

Laogia green for cone 6 ox

Laogia green on a bmix bowl

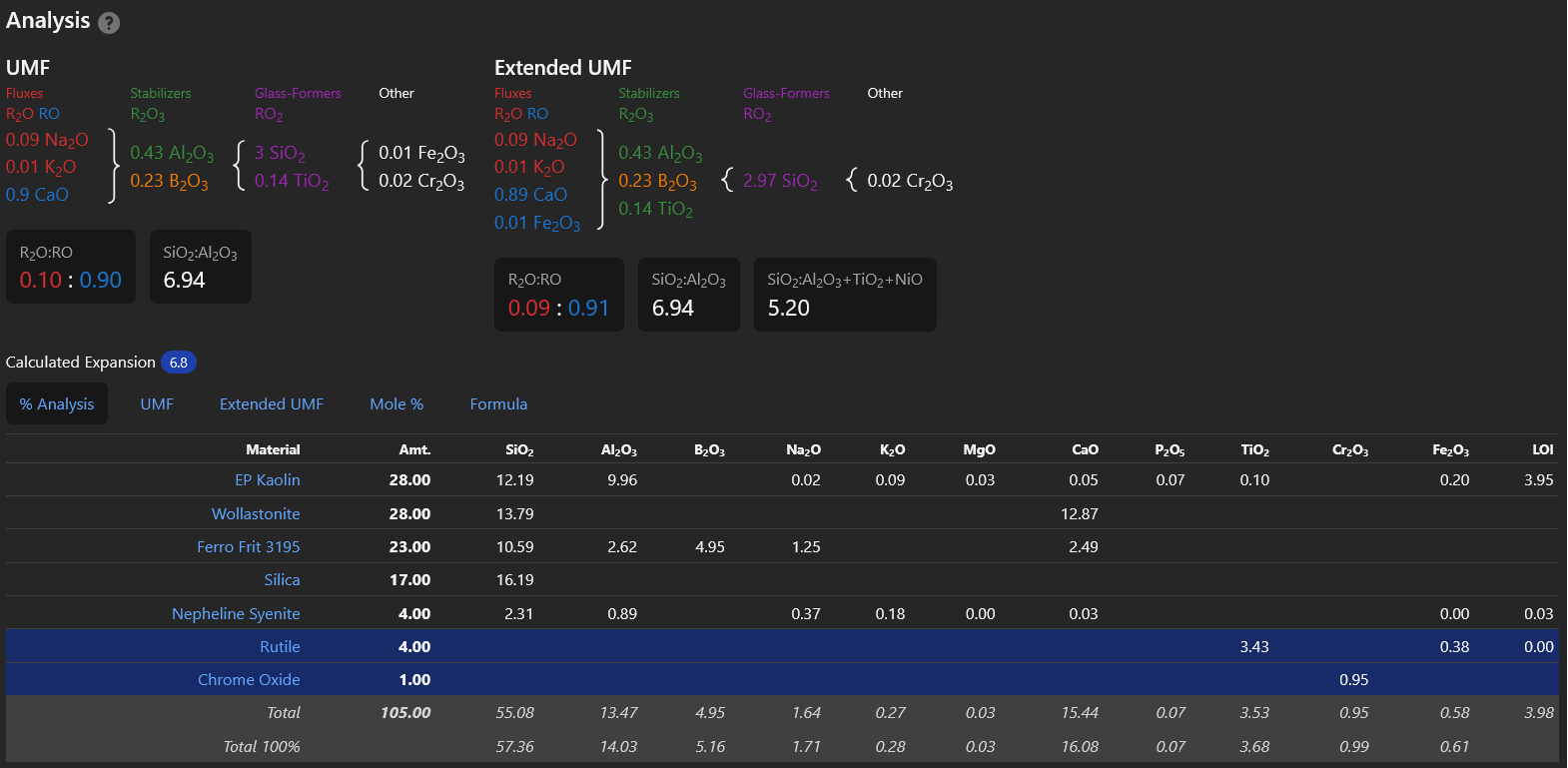

The molar amounts for the Laogia green recipe

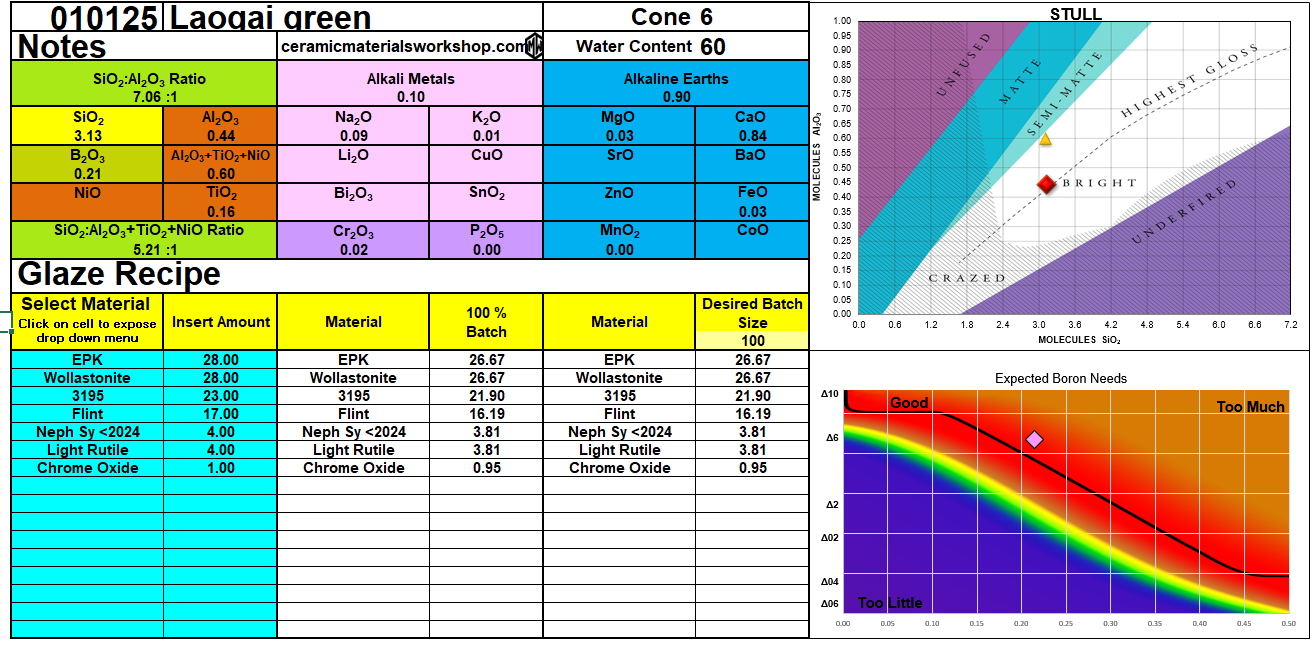

Most people want the recipe but some of us are trained in the (unity molecular formula) UMF. Following the UMF allows us to change around the materials based on their chemistry instead of the materials; The molar amounts are the recipe to us, not the ingredients. Here is the problem. Not all calculators are built the same. Do you notice how Glazy.org has two different UMFs/ Molar amounts? One is a different type called the extended UMF while the other is the basic one. The silica is a little off, the iron is put in with the alkaline earths instead of “other” column, the flux ratios are different, the silica to alumina ratios are different (which will effect the opacity; about a third of the things are a little off or missing all together. If you gave someone like me the UMF instead of the recipe and we used different calculators or even UMFs we would have major differences in glaze outcome. This is the easiest example I can give in house. Let’s take a look at the same recipe in the Ceramic Materials Workshop calculator.

The for Laogia green from the Ceramic Materials Workshop.

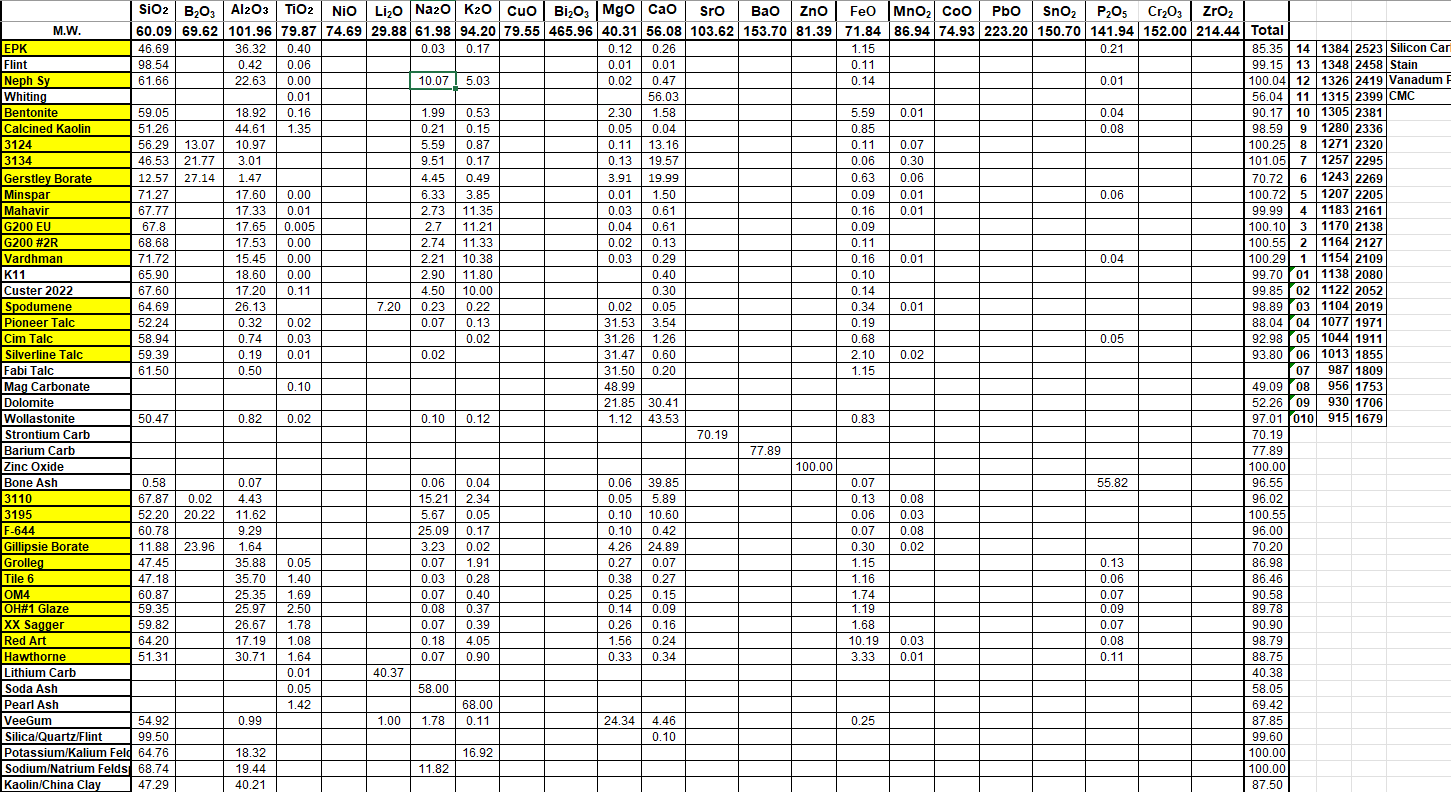

In my experience the Ceramic materials workshop glaze calculator gives more accurate info and even a boron scale telling you how much boron is too much for your cone. Let’s look at the recipe though. The same recipe input into the CMW calculator gives less boron, more silica, more alumina, it counts the trace amounts of Mg0 (glazy did not), more tin oxide, more iron, and less calcium. Given the CMW UMF counts materials before and after specific years but I know they keep up with their chemical analysis vs something like Digitalfire in-site live which I do not know. This makes sense because the chemical analysis of minerals change as the minerals and pits themselves change. EPK from before 2024 is different from the EPK we have now by small amounts. This means if the calculator you use has not updated the chemical analysis of a mineral for 20+ years and the mineral has changed pits or purity, your calculator will have to be updated to keep up. This is why it’s important to understand that calculators are not universal. Luckily for us the CMW posts the most up to date chemical analysis on the final page of their calculator.

1/3 of CMWs chemical analysis for each mineral as of 2025.

Want to know a secret?… The recipe (Laogai green) I used in this example has the closest molar amounts I could find in comparison. When I put in something like one of my cone 6 red glazes for oxidation the numbers are very different. Some calculators count things like Iron in with the earth fluxes and copper in with the metal fluxes. The colored oxides aren’t just “added color” they count as part of the chemistry, they matter when it comes to things like the strength of the glaze. Imagine, if the strength of your glaze is determined by counting things like iron in the flux ratio of Metal and earth fluxes and your calculator has not been accounting for it… Do you really know the flux ratio I.E the strength of your glazes?

I’m not making this blog to tell you to fear any calculator, I am making this blog to tell you to make sure your calculator is updated as materials change and to not be to dependent on any one calculator for an extended period of time. I use 4 different calculators. Some glazes are more difficult than others and need a different approach or have very tight amounts in order to work properly. Were not even talking about specific gravity or viscosity.