Playing with bismuth in cone 6 part 2 (my apology to bismuth)

After taking pictures and sitting with the test tiles from “playing with bismuth (prt 1) https://www.earthnationceramics.com/blog/playing-with-bismuth-what-are-you , I notice something; Something I have been looking for a long time. A strange iridescent glow when the sun hits it just right. I never noticed it before but now that I do, I have to test it. Two things people who have experience with bismuth usually say (but never show me the tests) is that bismuth “stiffens” up glaze and sometimes makes yellowish purples. Well, I am here to confirm that. It does in fact stiffen up glaze, it can in fact be used at cone 5/6 ox, and it will make slight purplish glow if done right. Let’s take a look at the tests in my last blog .

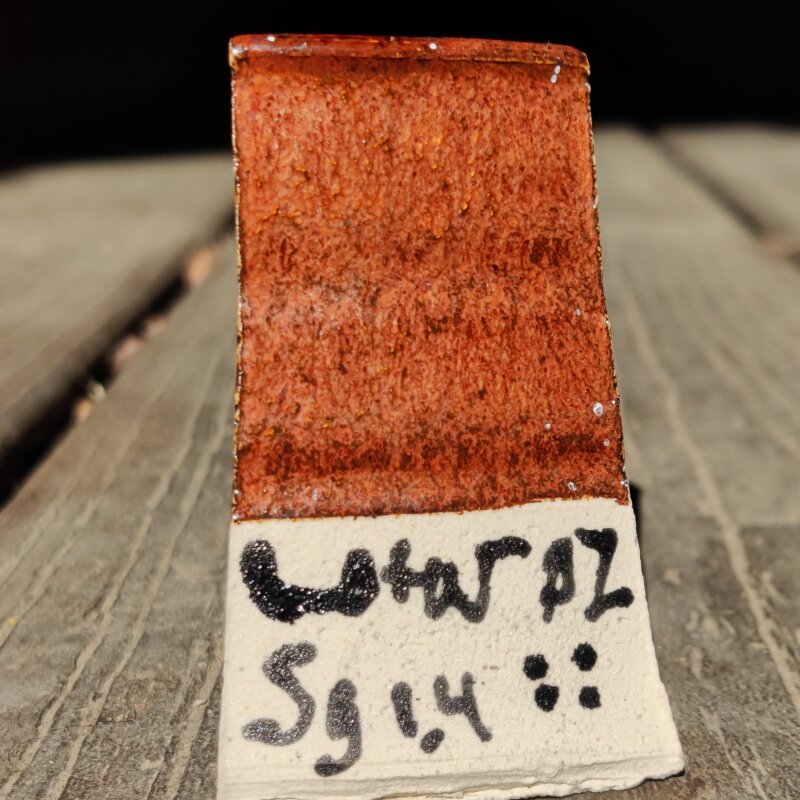

BZ

SG: 1.4

Clay: bmix

Application : 4 second dip

Cone : ^5 ox ( small kiln)

Noes: Notice anything? I have been working with this type of glaze for a long time (oxidation iron reds, not bismuth) My theory is that iron reds are just crystal glazes in disguise. See the little clumps of dots? That’s the red. But look at how clean that glaze line is…. Little to no movement…. Stiff…. Some would say.

BZ

SG: 1.4

Clay: bmix

Application : 5 second dip

Cone : ^5 ox ( small kiln)

Notes: Still no movement.

Here is what I did not appreciate about bismuth. The material itself doesn't make any huge color change nor make crystals right away. A problem that I have always had with most of my deep iron saturated reds at cone 6 ox is that the iron “cries”. My iron crystals streak instead of being round little stars. But do you see the tile above? No streaks. Here, let’s look at an example.

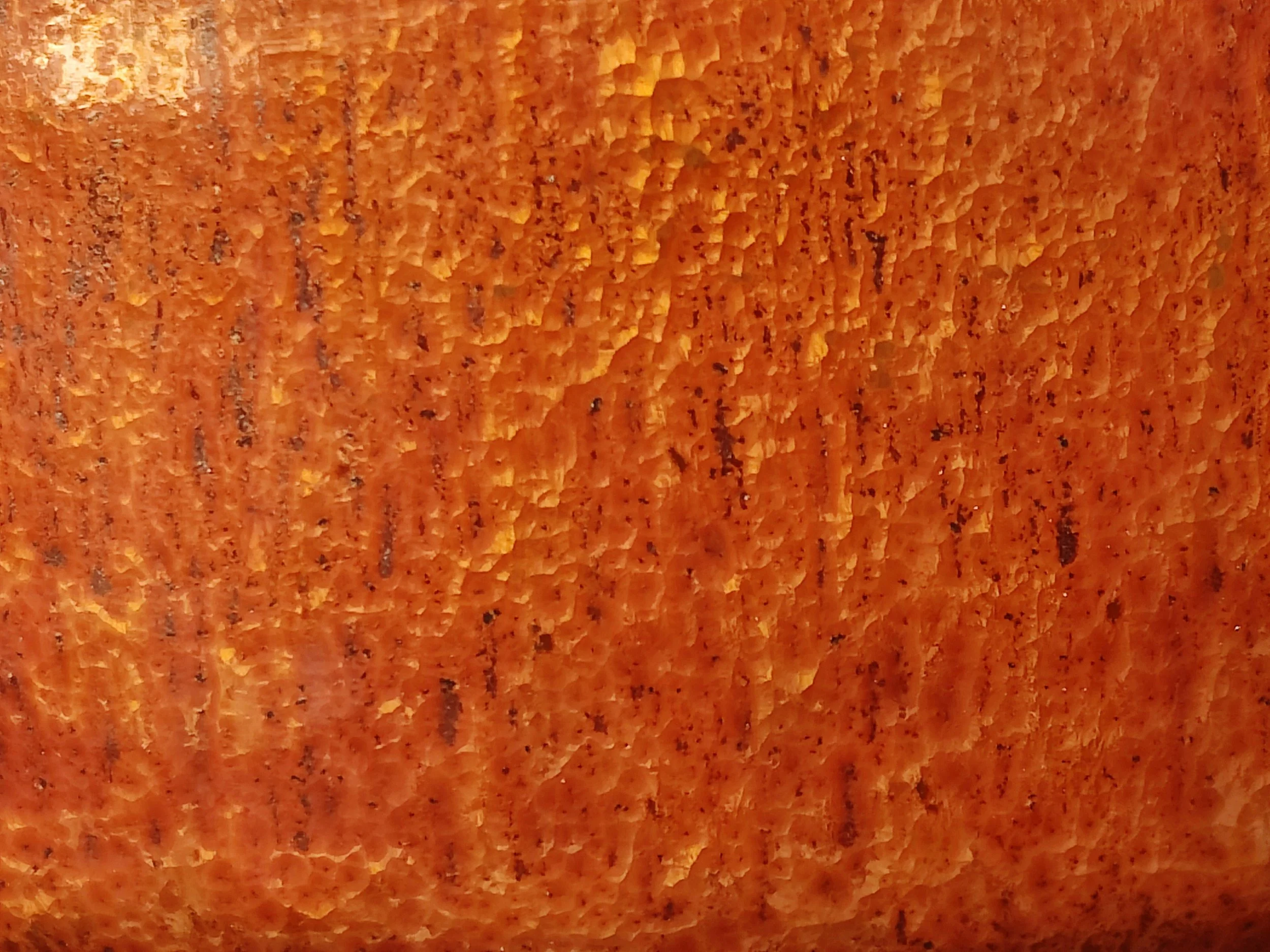

See it? The iron crystals in my usually recipes are not stars, they are streaks. This is normal for me. I can get the color red all day every day from cone 5-7. I could not figure out how to make the iron take round form instead of streaking or crying like this. Here, lets take a look at some more.

Iron Streaks

Still a little streaky.

Now go back to the first image at the top of this blog; notice anything? No streaking! Once I noticed this I ran to the glaze calculator to reformulate an entirely new glaze. I have always been told that crystal glazes (which are essentially what iron saturated reds in oxidation are) need to run a little. They often have low alumina, low silica, good movement/ running to them. But notice the bismuth glazes at the top of this blog has little to no running even at 11%; It’s “stiffening”. When people say bismuth stiffens up the glaze they mean it allows for less movement in the glaze. This, I believe , is what's helping my iron streaks keep their star shape. Now let’s look at the recipe I made last week with 4% bismuth.

Donte's Red materia

Application : 3 second dip

SG 1.3

clay: b-mix slip cast

cone : 6 ox

Viscosity tuning: none

Notes: see that opalescent shine? The iron no streaking? That very very slight purple? This is what people were talking about.

Donte's Red materia

Application : 5 second dip

SG 1.3

clay: b-mix slip cast

cone : 6 ox

Viscosity tuning: none

A closer look

Of course no test is complete without a double test to confirm. So

Donte's Red materia on b-mix tile

Application : 3 second dip

SG 1.3

clay: b-mix slip cast

cone : 6 ox

Viscosity tuning: none

Do you see how the iron bursts are now round? Take a closer look.

I have been treating bismuth like an alkali mental flux. Everyone else doesn't talk about it like that. Although glazy and CMW puts it in the metal flux of the UMF, it’s not a very strong flux. You can use it like an additive. The weight of the ingredient doesn't really count either, it’s all about how much if it is in the recipe by comparison to everything else. 4% in one recipe may be the same as 11% in another based oh how much of the other ingredients are with it. I don’t want anyone reading this blog and thinking “ So I can just put 4% in to any recipe as an additive and it'll be cool”… NO.

With that in mind I started treating it like an additive . I created a whole new recipe, one that I knew had a high probability of turning red at cone 6 ox with no issues, and added 4% (roughly 0.015n metal flux for this recipe in the UMF) which brought up the metal flux by about 0.02 and it turned out great. I personally think that you can add bismuth oxide a little over 0.01 - 0.015 and you'll get a small effect. This has confirmed what I originally thought about some glazes having a weird shine to them and getting way better iron crystals than I ( a person who can throw together a recipe or a cone 6 ox red in an hour) can. I think I know what they did now, They added a little bismuth. As a bonus test I put it at cone 7 for a 20 min hold in my smaller kiln on one of my Megaman slip cast test tiles. The working theory with crystal glazes is that the higher the heat, the less crystals you get. Of course it worked for the iron glazes I have been making BECAUSE THEY ARE CRYSTAL GLAZES!

Less crystal nucleation, still getting stars instead, not streaks. Imagine a bunch of little crystals like this together at cone 5…… spoiler alert… it was the first test tile you saw in this blog ;)

Here are more of my tests; just for eye candy.

Donte’s red materia on recycles clay. 4 layers, cone 5.5 in large kiln.

Super close up of Donte’s red materia on porcelain clay. Cone 6 ox. 3 second dip.

Now…. It’s not all good. I played with some of my phase separation glazes with bismuth in them and they changed a little. Let’s get a base line for this test.

Donte’s palmon green. Sg 1.45 . 3 second dip. recycled clay. cone 6 ox

This is one of my new phase separation glazes , Palmon green. Look closely, no crazing (I even left a little light on there so you can see). Now lets add a little bismuth.

Same glaze on dragon fruit.

Look closer. You see that?! See the little crazing! I have used this glaze on this clay body before and it has never crazed like this. The problem with crazing is that it’s insidious. You would have never known adding a little bismuth changed the thermal expansion so slightly that is caused crazing because the color of the glaze itself is in the way. You need to look very very close to even know it’s there. This is less of a problem with bismuth and more of a warning. Do not just add 2-4% bismuth by weight and assume it’s all good. It will change things and you ought to note these changes closely.

I am for sure going to start putting about 2-3.5% or so bismuth into my already complete glazes, especially the lower silica and alumina ones. Take this as my public apology to bismuth. I put a fish on land and was surprised it could not swim. I now understand one of the places it can do real work.